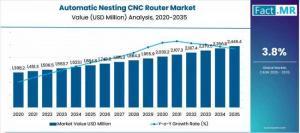

United States leads with ~30% share in Automatic Nesting CNC Router Market rising to USD 2,446.4 M by 2035 at 3.8% CAGR

Automatic Nesting CNC Router Market rises to USD 2,446.4M by 2035 Precision cutting, CAD/CAM integration, and automation drive efficiency at 3.8% CAGR.

ROCKVILLE PIKE, MD, UNITED STATES, November 11, 2025 /EINPresswire.com/ -- The global Automatic Nesting CNC Router Market is projected to grow from USD 1,684.8 million in 2025 to USD 2,446.4 million by 2035, at a 3.8% CAGR. Demand is fueled by precision cutting, material optimization, and digital workflow integration in furniture and woodworking sectors. Custom furniture trends and Industry 4.0 adoption are enabling cost reductions and higher throughput. Growth is particularly strong as CAD/CAM software and automation become central to modern factories.Furniture and woodworking manufacturers now face rising pressure to improve yields, reduce waste, and shorten lead times. Automation allows small, mid, and large-scale enterprises to manage complex, customized designs efficiently. This makes routers an essential investment for repeatable quality, speed, and profitability.

To access the complete data tables and in-depth insights, request a Discount On The Report here: https://www.factmr.com/connectus/sample?flag=S&rep_id=5748

Fast Facts

Market Size 2025: USD 1,684.8M

Market Size 2035: USD 2,446.4M

CAGR (2025–2035): 3.8%

Leading process type: Single head

Leading working area: 5000–7000 sq. inches

Top application: Wood

Key regions: United States, Germany, Japan

Purchase Full Report for Detailed Insights

For access to full forecasts, regional breakouts, company share analysis, and emerging trend assessments, you can purchase the complete report here: https://www.factmr.com/checkout/5748

What is winning and why

Efficiency, material yield, and digital integration drive adoption across furniture and woodworking.

Product – Single head routers: cost-effective, ideal for SMEs

Material – Wood applications: dominant, high demand for modular/custom furniture

Process – CAD/CAM integration: improves accuracy, reduces offcuts

Where to play

Direct sales to manufacturers, distributor networks, and B2B platforms dominate.

United States: 1.1% CAGR, custom cabinetry and modular furniture demand

Germany: 5.1% CAGR, precision engineering and Smart Factory adoption

Japan: 4.5% CAGR, modular and space-saving furniture demand

What teams should do next

R&D

Develop multi-process routers for high-volume, complex cuts

Enhance software-driven nesting for minimal material waste

Test automation integration with conveyors and robotic handling

Marketing & Sales

Run case studies highlighting cost savings and precision gains

Offer end-user trials with custom furniture manufacturers

Promote modular and “lights-out” production capabilities

Regulatory & QA

Ensure compliance with CE and DIN safety standards

Certify dust extraction, emergency stops, and operator safety

Implement preventive maintenance protocols for uptime assurance

Sourcing & Ops

Secure reliable spindle, tooling, and control electronics suppliers

Develop dual sourcing for high-demand components

Optimize logistics for regional deployment and installation support

Three quick plays this quarter

Launch CAD/CAM-enabled router pilot in mid-sized workshops

Demonstrate multi-process routers for modular furniture production

Integrate vacuum table and tool-change automation for new clients

Have a specific Requirements and Need Assistant on Report Pricing or Limited Budget please contact us – sales@factmr.com

The take

Automatic nesting CNC routers are moving from productivity tools to strategic assets. Manufacturers who integrate precision, digital workflows, and automation will achieve higher material yields, faster cycles, and sustainable cost savings. Adoption will continue to accelerate as modular and customized furniture drives demand.

Media line

For analyst briefings or custom cuts by process type, working area, application, and region, contact FACT MR

To View Related Report :

USA Carboxymethyl Cellulose Industry Analysis https://www.factmr.com/report/usa-carboxymethyl-cellulose-industry-analysis

USA Tungstic Acid Industry Analysis https://www.factmr.com/report/usa-tungstic-acid-industry-analysis

USA pH Control Industry Analysis https://www.factmr.com/report/usa-ph-control-industry-analysis

USA Bio-Based Acetic Acid Industry Analysis https://www.factmr.com/report/usa-bio-based-acetic-acid-industry-analysis

S. N. Jha

Fact.MR

+1 628-251-1583

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.