Smart Manufacturing Market In 2029

The Business Research Company’s Smart Manufacturing Global Market Report 2025 - Market Size, Trends, And Global Forecast 2025-2034

LONDON, GREATER LONDON, UNITED KINGDOM, January 12, 2026 /EINPresswire.com/ -- Smart Manufacturing Market to Surpass $748 billion in 2029. In comparison, the Software Products market, which is considered as its parent market, is expected to be approximately $2,895 billion by 2029, with Smart Manufacturing to represent around 26% of the parent market. Within the broader Information Technology industry, which is expected to be $12,711 billion by 2029, the Smart Manufacturing market is estimated to account for nearly 6% of the total market value.

Which Will Be the Biggest Region in the Smart Manufacturing Market in 2029

Asia Pacific will be the largest region in the smart manufacturing market in 2029, valued at $331,235 million. The market is expected to grow from $158,675 million in 2024 at a compound annual growth rate (CAGR) of 16%. The rapid growth can be attributed to the demand for condition monitoring and predictive maintenance and rising investments in industry 4.0.

Which Will Be The Largest Country In The Global Smart Manufacturing Market In 2029?

The USA will be the largest country in the smart manufacturing market in 2029, valued at $175,590 million. The market is expected to grow from $102,461 million in 2024 at a compound annual growth rate (CAGR) of 11%. The strong growth can be attributed to the demand for condition monitoring and predictive maintenance and rising investments in industry 4.0.

Request a free sample of the Smart Manufacturing Market report:

https://www.thebusinessresearchcompany.com/sample_request?id=8574&type=smp

What will be Largest Segment in the Smart Manufacturing Market in 2029?

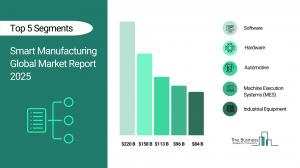

The smart manufacturing market is segmented by component into hardware, software and services. The software market will be the largest segment of the smart manufacturing market segmented by component, accounting for 57% or $427,610 million of the total in 2029. The software market will be supported by rising adoption of manufacturing execution systems that enable real-time production tracking and workflow optimization, the increasing use of industrial internet of things platforms that integrate data from machines and sensors, the growing deployment of advanced analytics and artificial intelligence software that improves decision making and predictive maintenance, the expanding implementation of digital twin software that enhances simulation and process optimization, continuous improvements in quality management software that ensure consistent product standards, the demand for supply chain management and planning tools that improve coordination and visibility, the increasing use of human machine interface software that enhances operator control and monitoring, the need for cybersecurity software that protects connected manufacturing environments, the adoption of cloud based manufacturing applications that offer scalability and remote access and ongoing investments in software solutions that support automation, flexibility and data driven operations across modern industrial facilities.

The smart manufacturing market is segmented by technology into machine execution systems (MES), programmable logic controller (PLC), enterprise resource planning (ERP), SCADA, discrete control systems (DCS), machine vision, 3D printing and other technologies. The machine execution systems (MES) market will be the largest segment of the smart manufacturing market segmented by technology, accounting for 22% or $163,749 million of the total in 2029. The machine execution systems (MES) market will be supported by the growing need for real-time production monitoring that improves visibility across manufacturing lines, the increasing demand for automated workflows that reduce manual errors and enhance process consistency, the rising adoption of data-driven decision making that relies on accurate shop-floor insights, continuous advancements in integration capabilities that connect MES platforms with enterprise resource planning and industrial internet of things systems, the expanding use of digital work instructions that improve operator efficiency, the need for enhanced traceability to meet stringent quality and compliance requirements, the growing focus on reducing downtime through predictive and preventive maintenance modules, the adoption of advanced scheduling and sequencing tools that optimize production planning, the rising importance of energy and resource optimization across factories and ongoing investments in cloud-based and AI enabled MES solutions that support scalable, flexible and highly responsive manufacturing environments.

The smart manufacturing market is segmented by end-user into automotive, aerospace and defense, chemicals and materials, healthcare, industrial equipment, electronics, food and agriculture, oil and gas and other end-users. The automotive market will be the largest segment of the smart manufacturing market segmented by end-user, accounting for 26% or $192,364 of the total in 2029. The automotive market will be supported by the growing need for highly efficient and precise production processes used in vehicle assembly, component manufacturing and quality inspection. The segment benefits from the rising demand for advanced automation that helps improve productivity, reduce defects and ensure consistent vehicle performance. The shift toward electric vehicles, lightweight materials and connected mobility increases the need for digital design tools, real-time monitoring and flexible production systems. Continuous improvements in robotics, connected sensors and data analytics enable faster, safer and more reliable manufacturing operations. In addition, the push for shorter production cycles, better energy efficiency and enhanced traceability continues to strengthen the adoption of smart manufacturing solutions in the automotive industry.

What is the expected CAGR for the Smart Manufacturing Market leading up to 2029?

The expected CAGR for the smart manufacturing market leading up to 2029 is 13%.

What Will Be The Growth Driving Factors In The Global Smart Manufacturing Market In The Forecast Period?

The rapid growth of the global smart manufacturing market leading up to 2029 will be driven by the following key factors that are expected to reshape industrial operations, production efficiency, and supply chain management worldwide.

Rising Investments In Industry 4.0 - The rising investments in industry 4.0 will become a key driver of growth in the smart manufacturing market by 2029. As manufacturers invest more in cyber-physical systems, intelligent automation, IoT (internet of things) connectivity, cloud platforms, digital twins and advanced analytics, factories become increasingly capable of self-optimization and real-time decision-making. These investments establish the technological foundation needed for automated operations, seamless human-machine collaboration and interconnected production environments. With higher investment levels, companies can modernize legacy equipment, integrate end-to-end data flows and upgrade plant-level architectures to support smarter, faster and more resilient manufacturing. This steady capital infusion drives the transition toward highly automated, digitally orchestrated factories, positioning smart manufacturing as a core pillar of long-term industrial competitiveness. As a result, the rising investments in industry 4.0 is anticipated to contributing to a 1.5% annual growth in the market.

Demand For Condition Monitoring And Predictive Maintenance - The demand for condition monitoring and predictive maintenance will emerge as a major factor driving the expansion of the smart manufacturing market by 2029. Smart factories rely on continuous monitoring of equipment performance through sensors, edge devices and real-time analytics to identify early signs of wear, misalignment, or system inefficiencies before failures occur. Predictive maintenance frameworks allow factories to transition from reactive to proactive maintenance strategies, optimizing service schedules, minimizing production interruptions and extending equipment life cycles. This shifts operational priorities toward data-driven maintenance, where machine health insights guide both short-term interventions and long-term asset planning. As predictive maintenance becomes more central to factory operations, manufacturers increasingly adopt advanced IoT (internet of things) solutions, AI (artificial intelligence) algorithms and integrated monitoring tools, all of which reinforce the growth of smart manufacturing ecosystems. Consequently, the demand for condition monitoring and predictive maintenance is projected to contributing to a 1.0% annual growth in the market.

Government Support For Digital Transformation Initiatives - The government support for digital transformation initiatives will serve as a key growth catalyst for the smart manufacturing market by 2029. Many governments prioritize smart manufacturing as part of national competitiveness and economic development strategies, promoting digital adoption through innovation grants, tax incentives, workforce upskilling programs and standards for industrial connectivity and automation. This support lowers the financial and operational barriers associated with transitioning to intelligent production environments, enabling small and large manufacturers to adopt advanced automation, IIoT (industrial internet of things) platforms, AI (artificial intelligence) technologies and cyber-physical systems. By fostering a favourable innovation environment, governments help build a stronger foundation for digital ecosystems, industrial interoperability and technology-driven productivity growth, all of which directly support the expansion of the smart manufacturing market. Therefore, this government support for digital transformation initiatives operations is projected to supporting to a 0.7% annual growth in the market.

Growing Adoption Of Connected Devices - The growing adoption of connected devices will become a significant driver contributing to the growth of the smart manufacturing market by 2029. As more equipment, tools and production assets became equipped with connectivity features, manufacturers gained the ability to continuously capture machine-level data, monitor operating conditions and coordinate workflows with higher accuracy. This widespread device connectivity created the foundation for real-time operational visibility, where every process, from assembly lines to supply-chain movements. could be digitally tracked and managed. Connected devices also strengthened interoperability across hardware and software platforms, supporting seamless communication between machines, analytics systems and control architectures. Consequently, the growing adoption of connected devices is projected to contributing to a 0.5% annual growth in the market.

Access the detailed Smart Manufacturing Market report here:

https://www.thebusinessresearchcompany.com/report/smart-manufacturing-global-market-report

What Are The Key Growth Opportunities In The Smart Manufacturing Market in 2029?

The most significant growth opportunities are anticipated in the smart manufacturing software solutions market, the smart automotive manufacturing market, and the smart manufacturing and MES integration market. Collectively, these segments are projected to contribute over $415 billion in market value by 2029, driven by advances in process automation, real-time operational monitoring, and seamless integration of manufacturing execution systems. This surge reflects the accelerating adoption of smart manufacturing technologies that enable optimized production efficiency, predictive maintenance, and enhanced decision-making, fueling transformative growth within the broader smart manufacturing industry.

The smart manufacturing software solutions market is projected to grow by $241,681 million, the smart automotive manufacturing market by $93,635 million, and the smart manufacturing and MES integration market by $79,533 million over the next five years from 2024 to 2029.

The Business Research Company (www.thebusinessresearchcompany.com) is a leading market intelligence firm renowned for its expertise in company, market, and consumer research. We have published over 17,500 reports across 27 industries and 60+ geographies. Our research is powered by 1,500,000 datasets, extensive secondary research, and exclusive insights from interviews with industry leaders.

We provide continuous and custom research services, offering a range of specialized packages tailored to your needs, including Market Entry Research Package, Competitor Tracking Package, Supplier & Distributor Package and much more

Disclaimer: Please note that the findings, conclusions and recommendations that TBRC Business Research Pvt Ltd delivers are based on information gathered in good faith from both primary and secondary sources, whose accuracy we are not always in a position to guarantee. As such TBRC Business Research Pvt Ltd can accept no liability whatever for actions taken based on any information that may subsequently prove to be incorrect. Analysis and findings included in TBRC reports and presentations are our estimates, opinions and are not intended as statements of fact or investment guidance.

The Business Research Company

Americas +1 310-496-7795

Europe +44 7882 955267

Asia & Others +44 7882 955267 & +91 8897263534

Email: info@tbrc.info

Oliver Guirdham

The Business Research Company

+44 7882 955267

info@tbrc.info

Visit us on social media:

LinkedIn

Facebook

X

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.