2036 Strategic Analysis of the Chemical Recycling Feedstock Aggregation Market: Portfolio Priorities, Adoption Trends

Global Chemical Recycling Feedstock Aggregation Market Poised to Transform Circular Plastic Economy; Strategic Growth Forecast Through 2036

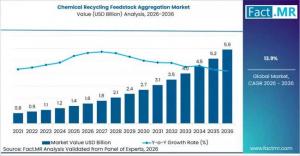

ROCKVILLE, MD, UNITED STATES, January 22, 2026 /EINPresswire.com/ -- As the global industrial sector pivots from a linear take-make-waste model toward a structured circular economy, the Chemical Recycling Feedstock Aggregation Market has emerged as the critical infrastructure link for sustainable material management. According to a new comprehensive strategic analysis by Fact.MR, a leading market research firm, the industry is entering a decade of rapid expansion driven by stringent environmental mandates and the urgent need for high-purity recycled resins.The report identifies 2026 as a pivotal inflection point for the industry. As the European Union’s Packaging and Packaging Waste Regulation (PPWR) and similar global mandates transition from guidelines to operational requirements, the ability to aggregate, sort, and process complex plastic waste streams is no longer a peripheral service—it is a strategic necessity for global manufacturing.

Request for Sample Report | Customize Report |purchase Full Report - https://www.factmr.com/connectus/sample?flag=S&rep_id=13789

Closing the Circularity Gap: The Who, What, and Why

The primary challenge in modern recycling is the Composition Trap. While mechanical recycling is effective for clean, homogenous plastics, it fails to address contaminated, multi-layer, or degraded materials. This is where Chemical Recycling Feedstock Aggregation intervenes.

Who: The market is driven by a convergence of B2B heavyweights in the food and beverage, automotive, and electronics sectors, alongside major petrochemical manufacturers like BASF, Dow, and SABIC, who are integrating chemically recycled feedstocks into existing production lines.

What: The industry encompasses the hardware, digital tracking systems (such as RFID and blockchain), and logistics networks required to collect and prepare post-consumer and industrial waste for advanced recycling technologies like pyrolysis and depolymerization.

Why: Unlike mechanical methods, chemical recycling returns plastic to its molecular state, creating virgin-quality resin. Feedstock aggregation ensures a consistent, high-volume supply of raw material, which is currently the single largest bottleneck for the $15 billion advanced recycling sector.

Data-Driven Market Insights and Projections

The Fact.MR report highlights several key growth catalysts and data points that will define the market trajectory between 2026 and 2036:

Regional Growth Leaders: India and China are projected to lead global expansion with CAGRs exceeding 10%, fueled by massive domestic packaging sectors and government-led circular economy initiatives. The United States and Germany follow closely, supported by advanced technology integration and material sovereignty strategies.

Feedstock Dominance: Polyethylene (PE) and Polypropylene (PP) remain the most sought-after feedstocks, together accounting for a significant portion of the aggregation demand. Flexible packaging and rigid bottles are the primary sources, representing nearly 35-40% of the market share.

Technological Shift: The market is seeing a transition toward depolymerization and pyrolysis, which allow for the recovery of monomers from multi-layer films—a waste stream previously considered unrecyclable.

Strategic Relevance for Industry Leaders

For investors and industrial leaders, the aggregation market represents a high-value opportunity. We are witnessing a structural shift where recycled waste is being reclassified as a strategic commodity, says the lead analyst at Fact.MR. By 2026, sustainability will evolve from a compliance checkbox into the central engine of business strategy. Companies that secure their feedstock pipelines today will be the market leaders of the 2030s.

However, the path is not without hurdles. The report notes that establishing state-of-the-art aggregation and chemical recycling facilities requires significant capital—often ranging from $50 million to $200 million. Success in this space depends on the integration of AI-driven sortation and digital product passports to validate the origin and purity of recycled content.

Outlook 2026–2036

The next decade will be defined by the maturation of these supply chains. As chemical recycling capacity moves from pilot projects to commercial-scale operations, the role of specialized aggregators will become indispensable. The market is expected to facilitate a 25% annual growth opportunity in the advanced recycling sub-sector, fundamentally transforming how society values and manages plastic resources.

To View related Reports:

Food Recycling Machine Market

https://www.factmr.com/report/1317/food-recycling-machines-market

Food Waste Recycling Machine Market

https://www.factmr.com/report/2266/food-waste-recycling-machine-market

Metal Recycling Baler Market

https://www.factmr.com/report/4094/metal-recycling-baler-market

Lithium-ion Battery Recycling Market

https://www.factmr.com/report/lithiumion-battery-recycling-market

S. N. Jha

Fact.MR

+1 628-251-1583

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.